Last

30 min

Targeted audience

Technical Service Manager

Improvement Process Engineer

Logistics Expert

Operator

Employee

New employee

Educational Objectives

Understand organization of production flows in straight flows and continuous flows, in a JIT system.

Know straight flows parameters

Strengths

Educational expertise

Certificate of validation delivered at the end of the training

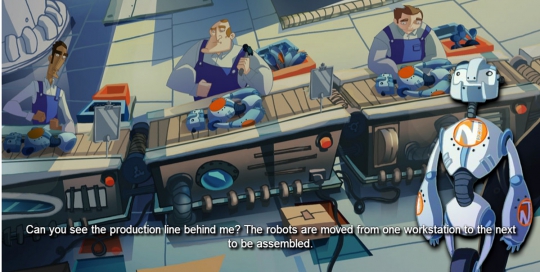

« Visit Nice Tech plant, producing robots with its boss, Claude Vallon, and the Moïyra Tech robot. »